Software Platform

NDT NDE Software Platform

VAREX IMAGING NDT SOFTWARE OFFERS SUPERIOR QUALITY IMAGE ACQUISITION

Whatever your NDT/NDE software needs, we’ll work with you to customize innovative solutions that deliver essential data to maximize your productivity and ensure your safety.

Reliable & Powerful Single Platform for all Varex Imaging NDT Solutions

Doppler Z-MLE: Varex Imaging NDT Solution’s Game-Changing Patented Tool for Pipe Corrosion Testing

DISCOVER WHAT’S INSIDE

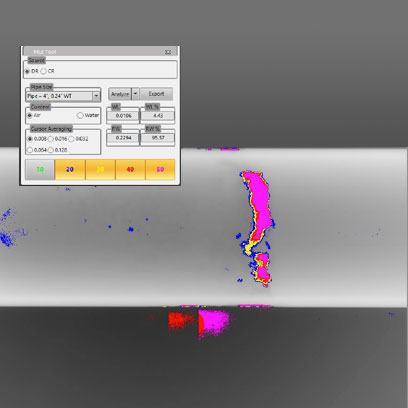

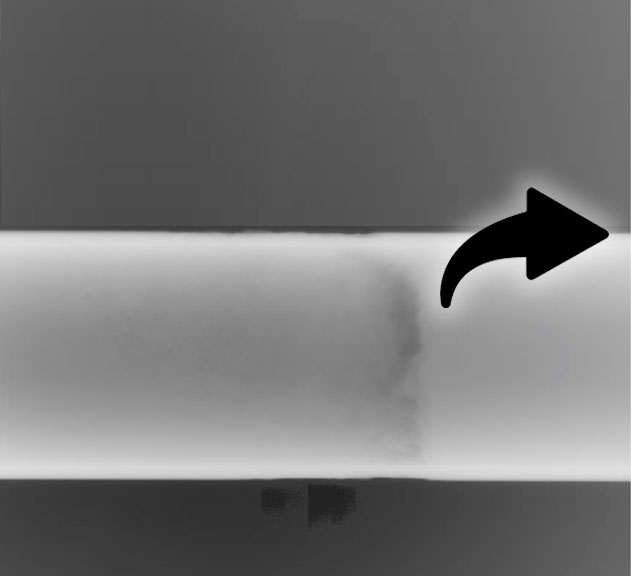

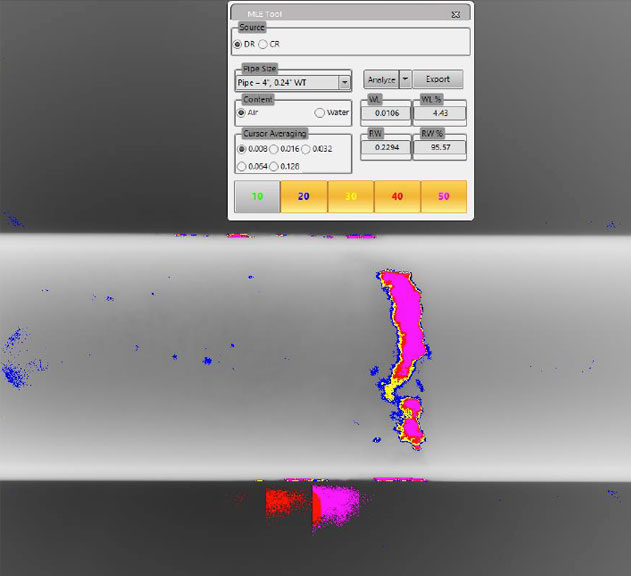

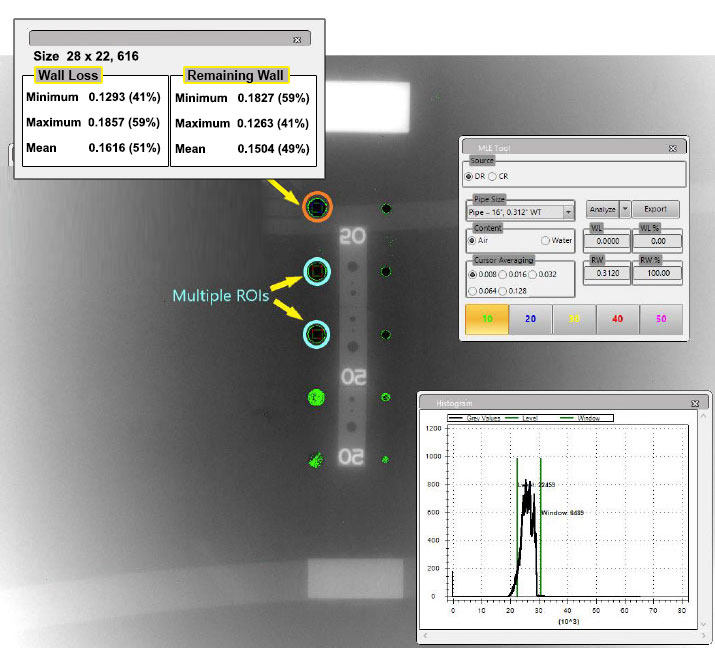

PIPE CORROSION INSPECTIONS

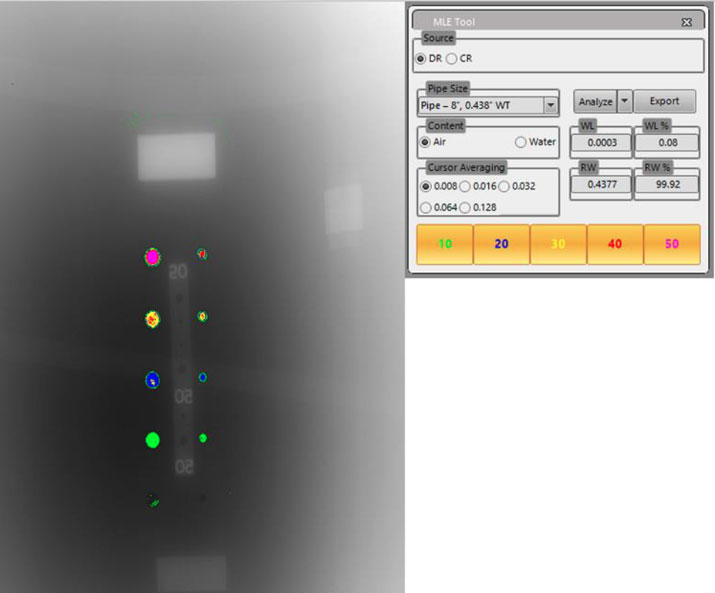

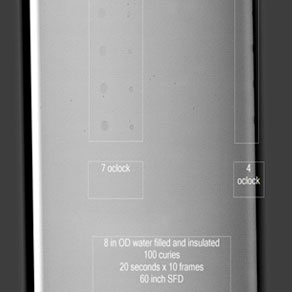

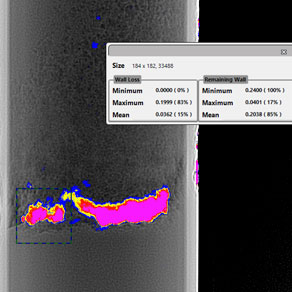

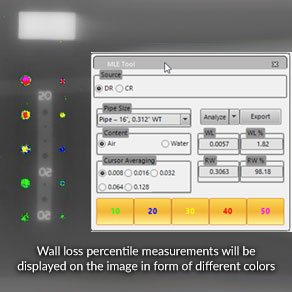

Doppler Z-MLE (material loss estimator; branded name) is Varex Imaging NDT Solution’s patented pipe wall-loss measurement tool. Traditional methods allow only qualitative assessments as they provide only limited information. With the Varex Imaging NDT Solution’s MLE tool, it is possible to convert an entire radiograph into a wall loss map, with color-coding that allows radiographers to determine exact wall loss quantity in real-time. We’ve also designed the MLE with the source and detector on the pipe so you can make adjustments as needed, even on-site.

With our MLE tool, you can conduct pipe corrosion inspections swiftly and safely while operating assets continue functioning at optimal capacity.

WALL LOSS ESTIMATOR

The MLE tool is intuitive and requires the following inputs: source, pipe diameter, wall thickness, and whether it’s filled or empty of content. If you have questions about using our MLE tool for a pipe corrosion inspection, please don’t hesitate to contact us.

Real-Time Measurement of Wall Loss Information

Imaging Utilizes the Depth Information on the Z-Axis

Service is Our Cornerstone

Superior Service

Leading to Valued

Relationships

We provide personal customer service by thoroughly listening, planning, and working side-by-side to implement solutions and build strong client relationships.

Expert NDT Training

WE BELIEVE THE BEST SOLUTIONS ARE BUILT FROM WORKING TOGETHER

STRONGER. FASTER. BETTER.

Varex Imaging NDT Solutions is your solution to assist with moving from traditional film to digital Xray. By doing this, our clients have decreased costs (no insulation removal or film costs), and downtime (real-time image evaluation) for an increase in ROI.

COST

REDUCTION

ACCURACY OF

IMAGES

TURN-AROUND

INSTANT

INDUSTRIES WE HELP

Aerospace/Aviation

We create mission-critical systems and applications with superior solutions designed for aircraft inspection.

Metals/ Manufacturing

We build custom systems for enhanced productivity within manufacturing & industrial operations.

Military/Defense

We serve alongside the U.S. military and allies globally, placing 200+ digital radiography solutions.

Energy: Power Gen

We offer computed radiography solutions that provide early detection of cracks and structural degradation in nuclear power plants.

Energy: Oil & Gas

We help eliminate the complexities of flaw detection in refinery equipment to prioritize safety and efficiency.

NDT Service Providers

We provide a wide range of solutions for organizations that perform inspections for customers working in capital-intensive industries.